Jar Test Procedure

Apply only enough hydrated lime to raise the pH to between 7. For example if nickel is the main metal of concern adjust the final pH to 10 to fully optimize the effects of hydroxide precipitation.

P10 9 Jar Test Experiment Youtube

Jar Testing Procedures The following jar test procedure uses alum aluminum sulfate a chemical for coagulation flocculation in water treatment and a typical six-gang jar tester.

. Below we lay out how to jar test coagulants and flocculants in 9 simple steps. Take several readings before recording final NTU results. In each beaker add 1ml of the flocculant solution and mix for 1 minute.

PH lower than 65 may require buffering with a sprinkle of hydrated lime. There is no single jar test procedure will duplicate all of these processes for all plants however experience shows that jar test procedures can be individually tailored to accurately predict. The solution can be achieved by taking 125 ml of flocculent adding it to 500 ml of water mixing thoroughly by shaking or mixing.

A jar test procedure as described above can help to establish the optimum pH within the 75 to 11 range. Jar tests are conducted on a four- or six-place gang stirrer which can be utilized to. Test Procedure Preparing the Samples.

A special note of thanks to Larry Rader former Program Specialist of the WVRWA for his enthusiasm in promoting the benefits of jar testing. Jar Testing Procedure. Individual jar tests were conducted from 2018to 2020 for 37 of the states public surface water treatment plants using var ious treatment technologies.

What is jar test. Field and laboratory results validated the developed jar test and filterability procedures accurately predicting full-scale plant filtration performance and indirect organic reductions. By jar testing on a sample of wastewater generated from your production line significant benefits emerge such as p roduct compatibility and validation c orrect chemical dose and injection rate and projected use-cost.

The jar test is a method of measuring the effect of coagulation flocculation and sedimentation on turbidity. Although the procedure is not outlined in Standard Methods it is used in most water treatment plants to find the best coagulant dosages under varying conditions. For adjusting pH sodium hydroxide is recommended.

The results of this proce-dure can help optimize the performance of the plant. Measure and record the pH of the raw water samples prior to commencing the jar test. Generally the best performing products provide fast floc formation rapid settling.

Typically a 025 solution in water is created. This video goes over the basics of jar testing for drinking water treatment and provides a demonstration of the next-generation jar test procedure. First using a 1000 milliliter mL gradu-ated cylinder add 1000 mL of raw.

Syringe 25 mL from jar after 5 minutes of settling Attached filter holder housing 12 um membrane filter to syringe. Identify which coagulant chemistries you plan to. This procedure allows individual polymers to be compared on such criteria as floc formation settling characteristics and clarity.

Filter-to-waste 3-5 mL drip rate Filter directly into clean cuvette drip rate 15 mL50-90 sec Measure turbidity. Jar test is a pilot-scale laboratory test that simulates coagulation or flocculation with differing chemical doses. A Simplified Jar Test Procedure.

The jar test has been and is ah important drinking water treatment plant design process control and research tool. The standard jar test is a critical procedure for selecting the appropriate polymer for a aparticular clarification application. N the drinking water field the jar test is described as a.

Wastewater 369 Jar Testing Procedures By Dave Christophersen CWT D eciding On Coagulant Chemistries A. Acknowledgement The procedures outlined in this publication appear courtesy of the West Virginia Rural Water Association. However other common chemicals can be used -- such.

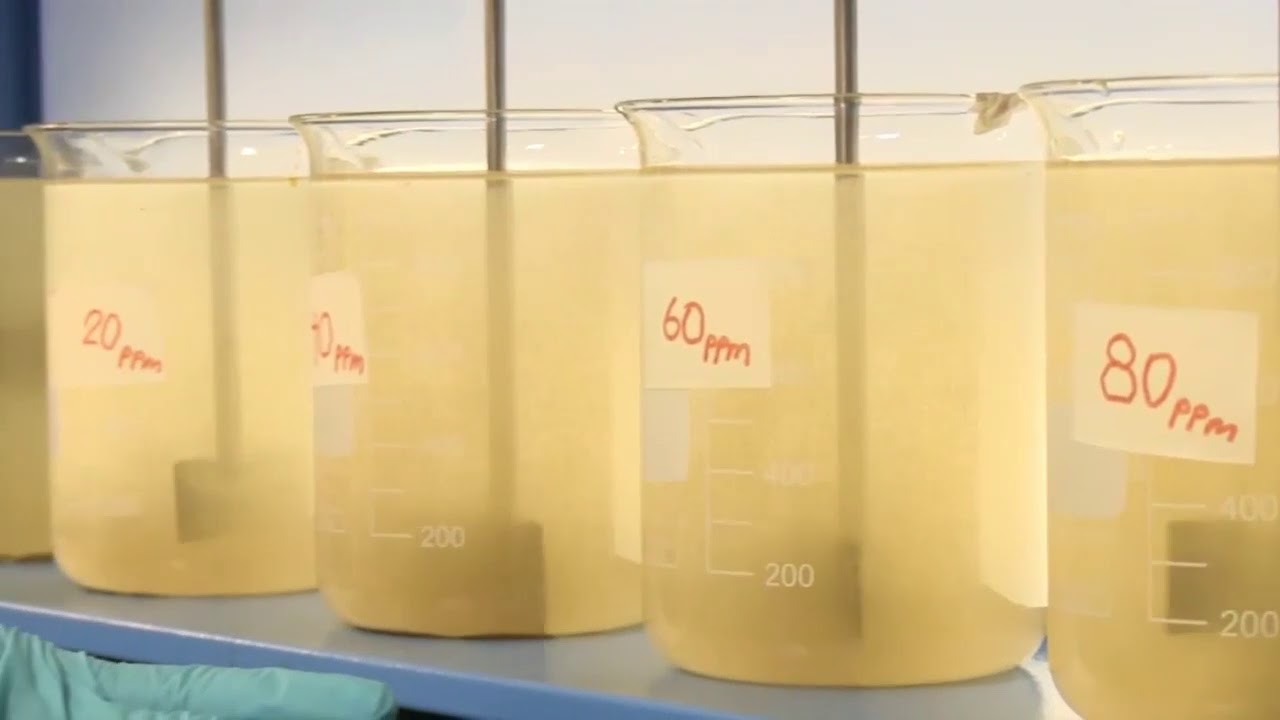

Adding 1ml of a 025 solution of flocculant to 500 ml of water equates to a dosage of 5 ppm. The purpose of the jar test is to estimate the minimum coagulant dose required to achieve certain water quality goals. Representative jar testing means that the jar test procedure will imitate the coagulation flocculation and settling conducted in the water plant.

Jar Test - Filterability Test. The jar testing procedure described herein is provided by Turbid Water Solutions to assist our.

The Importance Of Jar Test In Water And Wastewater Analysis

The Importance Of Jar Test In Water And Wastewater Analysis

0 Response to "Jar Test Procedure"

Post a Comment